CNC Milling

Computer numerical controlled (CNC) machining centers may be used in the production of myriad tools and components. Once cost-prohibitive, the tooling costs involved in these processes have continued to become substantially more affordable over time. This means that CNC milling services are more accessible now than ever.

Computer numerical controlled (CNC) machining centers may be used in the production of myriad tools and components. Once cost-prohibitive, the tooling costs involved in these processes have continued to become substantially more affordable over time. This means that CNC milling services are more accessible now than ever.

CNC milling can accommodate projects and runs of all sizes. The process allows for both low and high prototype volumes to be created quickly in adherence with even the strictest specifications.

MF Engineering is ISO 9001:2015 certified. We promote quality management and know what it takes to see your proposal through from beginning to end. In order to maintain maximum efficiency, we abide by Lights Out Lean manufacturing and Kaizen/5S.

All of our lead times are provided on a job-by-job basis. Emergency and rush services are available.

Offerings

MF Engineering offers a wide range of services. We use top-of-the-line machinery to create the components you need at the specifications you require. Our state-of-the-art facilities and experienced staff allow us to turn out quality pieces every time, and certified professionals oversee every step of your project.

Whether a part is undergoing milling, drilling, broaching, or any other process, you can rest assured we use the best machinery at our disposal in the hands of watchful, knowledgeable staff.

-

Services/Processes

- Assembly

- Milling

- Drilling

- Deep hole drilling

- Boring

- Tapping

- Pressing

- Reaming

- External & internal threading

- Broaching

- Counterboring

- Countersinking

- Corner rounding

- Edge breaking

- Facing

- Pocketing

- Profiling

- Engraving

- Reaming

- Part marking

- Dot peening

Outside Secondary Services

- Anodizing

- Plating

- Passivating

- Surface grinding

- Welding

- Chemical etch / Chromating

- Laser engraving

- Heat treating

-

Equipment

CNC Vertical Machining Center

- Milling

- CAD design services

- CAM programming services

- Reverse engineering

- Machinery Axis: 3 – 4

- Max. part dimensions:

- Length: X 26″

- Width Y 14″

- Height Z 12″

- Tolerances:

- +/- .001″ for length, width, and height

-

Materials

Metals

- Aluminum

- Beryllium

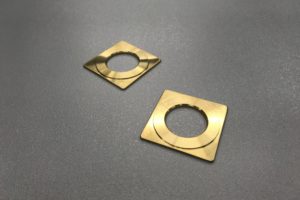

- Brass

- Bronze alloys

- Carbon steel

- Copper

- Iron

- Nickel

- Stainless steel

- Steel alloys

- Titanium

Exotic and Precious Metals

- Inconel

- Monel

- Platinum

- Silver

- Superalloys

Plastic Polymers

- ABS

- Acetal

- Acrylic

- Fiber-reinforced plastics

- Nylon

- Phenolic

- Polycarbonate

- Polyetherketone

- PTFE

- PVC

- Teflon

Our certified staff of industry professionals will work with you to create unique solutions that meet the unique needs and specifications of your application.To learn more about the CNC milling services offered by MF Engineering, contact us or request a quote today.